Bühler, a multinational enterprise with HQ base in Switzerland, is one of the world’s leading specialists and technology partners for plant, equipment, and services for processing basic foods and for manufacturing advanced materials. As the global leader in the supply of flour production plants, pasta and chocolate production lines, animal feed manufacturing installations, and aluminum die casting systems, the 150-year-old company operates in over 140 countries and generated sales revenues of CHF 2,409 million in the fiscal year 2012. Bühler has had its own affiliate in Bangalore India since 1992 and offers the complete product and service portfolio to the Indian market. It is India’s market leader in the supply of customized turnkey projects and provision of rice processing systems, flourmills, color sorters, and feed manufacturing plants. The enterprise also supplies equipment to specialized automotive companies. With 700 employees on payroll, of which 580 staff is regularly employed and the remaining are either contract workers or apprentices and trainees, Bühler India belongs to the fastestgrowing affiliates of the Bühler Group. Presently the company is setting up an R&D Laboratory and plans to expand the higher end manufacturing and research capacities within India to be closer to the needs of the fast growing market. The group enjoyed healthy growth of 26% CAGR and an annual turnover of 700 Crore INR during the fiscal year 2012/13, but has, like most manufacturers in India, been affected by the recent economic slowdown.

Addressing Skills Shortages through Training and HR Development

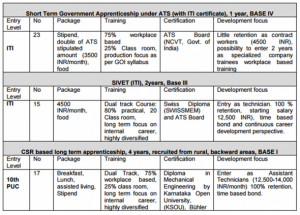

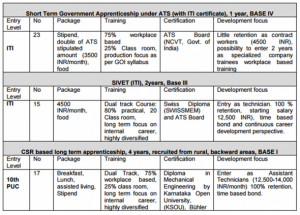

As Bühler India attaches importance to excellence in service and product development, training is a critical aspect to equip a highly skilled and flexible workforce with the competencies specifically required to operate Bühler’s specific technology (milling, coffee, snacks etc), which is currently not available in the labour market. Skills shortages are also prominent for welders, painters, poly and electrical mechanics, and it is difficult to retain trained middle level technicians and production professionals. However, with an average of 5%, mainly in the middle management level, attrition amongst regular employees is much lower than the industry average. There is still a critical skills shortage of women at all levels. Against these challenges, Bühler set up the Bühler Academy to foster talent for the enterprise and its customers through the provision of top-class training opportunities. The company builds technical, methodological and social skills related competencies as per the individual needs of the employees, apprentices and trainees. Since 2008, the Academy offers comprehensive apprenticeships and traineeships of various types and at different entry levels and increasingly engages in continuous skills training and skills up gradation of the existing workforce. With a long-term perspective to train and retain a capable workforce, Bühler India offers various apprenticeships and traineeships, which offer continuous jobs and career pathways within the enterprise. Through its CSR activity, the company offers longterm training opportunities to 15-20 top school performers from rural areas under a Bühler India’s specific 4-year-long structured apprenticeship programme, which leads to diploma for mechanical engineering that is obtained from the Karnataka Open University (KSOU). In the ongoing pilot project “Swiss-Indian Vocational Education and Training Initiative VET” (SIVET) Bühler offers a professional career plan with Swiss certification to talented ITI certificate holders who join as apprentices but get a specialized dual track apprenticeship (75% practical and 25% theoretical), which is intensely mentored for a duration of 2 years after joining as an ATS apprentice. SIVET apprentices, after attaining ATS and SWISSMEM certification, continue on the job training for another 2 years as regular employees. These two groups are part of a dual track training process, which offers a mix of classroom and practical experience with strong monitoring and mentor support and specific project work in separate learning premises and sometimes on the shop floor.

Another group, the largest group, includes the apprentices with ITI certificate joining under the ATS Scheme for a year to gain practical experience. Currently, there are 23 ATS apprentices with 2 being women. For this group the focus lies on getting practical work experience. In the case of ATS apprentices, they have usually assigned mentors whom they assist during their practical training.

Career Pathways for Apprentices

There are clearly defined career pathways associated with the type of training that is offered in Bühler, which also reflects in retention of apprentices (see table 8). With the exception of the ATS short-term apprenticeship, all the other apprentices/trainees within Bühler are retained. In the case of apprentices under AST, Bühler usually provides a stipend during the apprenticeship period double the stipulated amount and offers strong candidates to do company training and regular employment, but mostly offers contractual work on the shop floor, where they work as assistants for about 6-9 working months, before they move on. This period is again considered another on the job training opportunity; however, poor academic skills and workplace performance mostly lead to the decision within the enterprise not to renew the contract. This again reflects the challenges the company faces in recruiting ITI graduates on campus with the required academic and technical track records.

Overview of Training /Apprenticeship provision in EFD

Returns from Investments

With regard to ROI, there is a clear difference between the three types of apprentices, how fast cost recovery is expected to happen. For the SIVET apprenticeship, it is expected that cost recovery during the apprentice period is slower as production is only linked to their project related production, which is a part of the practical training. In the case of SIVET, the ROI consequently will only be recovered, at much higher level, when they officially work on the shop floor after their training period. 24 The typical ATS apprentice earns about 42,000 INR per annum, while a CSR apprentice and SIVET apprentice earns 68,000 INR for the first year. In contrast, an experienced and skilled technician in Bühler earns app. 40’000 INR per month. The company, as shown in the table below, spends an average 163,509 INR for each ATS apprentice per annum. While during the first 6 months, the contribution of the apprentices is minimal with 10% of the productivity of an average skilled employee within Bühler, the apprentice’s contribution in comparison to a skilled worker increases to 30% during the second half of the year. During the second 6 months, the enterprise gets a clear benefit from apprentices who contribute 154,364 INR and therefore, is able to recover the entire investments made into the apprentice during the apprenticeship period itself for ATS apprentices. As there are drop out cases, there are additional costs that occur from the investments into the apprentices who leave the enterprise. During the ATS year, Bühler generates for each INR invested 1.08 INR returns.